Hybrid Deep Learning Approach for Predictive Maintenance of Industrial Machinery using Convolutional LSTM Networks

DOI:

https://doi.org/10.26438/ijcse/v12i4.111Keywords:

Predictive Maintenanc, Convolutional Neural Networ, Long Short-Term Memory,, , Engine Failure, Industrial Machinery, Sensor DataAbstract

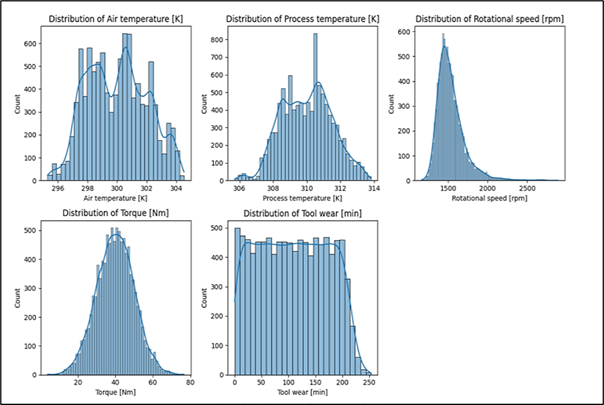

Predictive maintenance is crucial for minimizing unplanned downtime in industrial machinery. This research proposes a hybrid deep learning approach using Convolutional LSTM Networks (Conv-LSTM) for fault detection in wind turbine gearboxes. The Conv-LSTM model combines convolutional neural networks (CNNs) for spatial feature extraction and long short-term memory (LSTM) networks for temporal modeling, enabling it to capture intricate patterns in multivariate sensor data. The approach was evaluated on the AI4I Predictive Maintenance dataset from Kaggle, containing real-world sensor readings from an operational wind turbine gearbox. The Conv-LSTM architecture processes raw sensor data through convolutional and LSTM layers trained jointly to learn hierarchical representations of the gearbox dynamics. Extensive experiments demonstrated the model`s outstanding performance, achieving an impressive 97.9% accuracy in classifying whether a fault condition exists in the gearbox and a corresponding loss of 0.0059 after ten epochs of training. This high predictive accuracy allows wind farm operators to anticipate potential gearbox failures proactively, enabling timely maintenance and minimizing costly downtime. The proposed approach contributes to the efficiency and sustainability of wind energy operations.

References

[1] M. Pech, J. Vrchota, and J. Bedná?, "Predictive maintenance and intelligent sensors in the smart factory: a review," Sensors, Vol.21, No.4, pp.14-70, 2021. doi: 10.3390/s21041470.

[2] M. Hoffmann, S. Wildermuth, R. Gitzel, A. Boyaci, J. Gebhardt, H. Kaule, et al., "Integration of novel sensors and machine learning for predictive maintenance in medium voltage switchgear to enable the energy and mobility revolutions," Sensors, Vol.20, No.7, pp.20-99, 2020. doi: 10.3390/s20072099.

[3] N. Davari, B. Veloso, G. Costa, P. Pereira, R. Ribeiro, and J. Gama, "A survey on data-driven predictive maintenance for the railway industry," Sensors, Vol.21, No.17, pp.5739, 2021. doi: 10.3390/s21175739.

[4] Z. Huang, Y. Shen, J. Li, M. Fey, and C. Brecher, "A survey on ai-driven digital twins in industry 4.0: smart manufacturing and advanced robotics," Sensors, Vol.21, No.19, pp.6340, 2021. doi: 10.3390/s21196340.

[5] M. Dangana, S. Ansari, Q. Abbasi, and S. Hussain, "Suitability of nb-iot for the indoor industrial environment: a survey and insights," Sensors, Vol.21, No.16, pp.52-84, 2021. doi: 10.3390/s21165284.

[6] J. Olesen and H. Shaker, "Predictive maintenance for pump systems and thermal power plants: state-of-the-art review, trends and challenges," Sensors, Vol.20, No.8, pp.24-25, 2020. doi: 10.3390/s20082425.

[7] D. Duncker, W. Ding, S. Etheridge, P. Noseworthy, C. Veltmann, X. Yao, et al., "Smart wearables for cardiac monitoring—real-world use beyond atrial fibrillation," Sensors, Vol.21, No.7, pp.25-39, 2021. doi: 10.3390/s21072539.

[8] G. Callebaut, J. Mulders, G. Ottoy, L. Strycker, and L. Perre, "The art of designing remote IoT devices—technologies and strategies for a long battery life," Sensors, Vol.21, No.3, pp.9-13, 2021. doi: 10.3390/s21030913.

[9] G. Famitafreshi, M. Afaqui, and J. Melià-Seguí, "A comprehensive review on energy harvesting integration in iot systems from Mac layer perspective: challenges and opportunities," Sensors, Vol.21, No.9, pp.30-97, 2021. doi: 10.3390/s21093097.

[10] M. Grilli, D. Valerini, A. Slobozeanu, B. Postolnyi, S. Baloš, A. Rizzo, et al., "Critical raw materials saving by protective coatings under extreme conditions: a review of last trends in alloys and coatings for aerospace engine applications," Materials, Vol.14, No.7, pp.16-56, 2021. doi: 10.3390/ma14071656.

[11] S. Hamdan, M. Ayyash, and S. Almajali, "Edge-computing architectures for Internet of things applications: a survey,"

[12] M. Marchi, M. Penasa, A. Zidi, and C. Manuelian, "Invited review: Use of infrared technologies for the assessment of dairy products—Applications and perspectives," Journal of Dairy Science, Vol.101, No.12, pp.10589-10604, 2018, doi: 10.3168/jds.2018-15202.

[13] M. Paolanti, L. Romeo, A. Felicetti, A. Mancini, E. Frontoni, and J. Loncarski, "Machine Learning Approach for Predictive Maintenance in Industry 4.0," in 2018 14th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), pp.1-6, 2018. doi: 10.1109/MESA.2018.8449150.

[14] K. I. Masani, P. Oza, and S. Agrawal, "Predictive maintenance and monitoring of industrial machine using machine learning," Scalable Computing: Practice and Experience, Vol.20, No.4, pp.663-668, 2019.

[15] Y. Zhang, B. Xie, T. Chen, and L. Chen, "A deep learning framework for unsupervised anomaly detection in large-scale industrial data," IEEE Transactions on Industrial Informatics, Vol.15, No.8, pp.4620-4629, 2019.

[16] A.Goyal, N. Mahajan, and R. Jha, "Anomaly detection in industrial IoT: A survey," IEEE Communications Surveys & Tutorials, Vol.20, No.3, pp.2523-2553, 2018.

[17] Y. Xu, Y. Zeng, and X. Xu, "Anomaly detection in industrial time series: A survey," IEEE Transactions on Big Data, Vol.4, No.3, pp.372-389, 2018.

[18] M. Himmelspach, B. Knapp, M. Schmitt, and C. Becker, "A hybrid approach to anomaly detection in industrial systems," Journal of Intelligent Manufacturing, Vol.29, No.2, pp.429-439, 2018.

[19] R.Gopalan, V. Rajagopal, and V. Venkatasubramanian, "Anomaly detection in industrial systems using randomized matrix decompositions," IEEE Transactions on Industrial Electronics, Vol.66, No.3, pp.217-225, 2019.

[20] Y. Liu, H. Liu, L. Zhou, and J. Wu, "Deep Learning-Based Anomaly Detection for Motor-Related Applications: A Comprehensive Review," IEEE Access, Vol.9, pp.120616-120631, 2021.

[21] M. H. Yousaf, M. Faheem, N. Islam, M. Ali, and S. W. Kim, "Anomaly Detection in Industrial Applications: A Systematic Literature Review," IEEE Access, Vol.8, pp.86944-86968, 2020.

[22] M. Safdari, P. Jokar, and A. Ahmadi, "Anomaly detection in industrial processes with LSTM networks and deep autoencoders," Journal of Ambient Intelligence and Humanized Computing, Vol.11, No.10, pp.4519-4534, 2020.

[23] R. Gopalan, V. Rajagopal, and V. Venkatasubramanian, "Anomaly detection in industrial systems using randomized matrix decompositions," IEEE Transactions on Industrial Electronics, Vol.66, No.3, pp.217-225, 2019.

[24] Y. Jiang, Y. Han, L. Zhao, H. Liu, and B. Xu, "A Deep Learning Framework for Anomaly Detection in Industrial Internet of Things (IoT)," IEEE Transactions on Industrial Informatics, Vol.15, No.8, pp.4693-4701, 2019.

[25] F. Yuan, J. Zhu, and X. Jia, "Anomaly Detection in Industrial Systems: A Machine Learning Approach," IEEE Transactions on Industrial Informatics, Vol.14, no.8, pp.3667-3674, 2018.

[26] F. M. Bianchi and A. M. K. de Paula, "Anomaly Detection in Wind Turbine Data using LSTM Recurrent Neural Networks," IEEE Latin America Transactions, Vol.19, No.4, pp.567-573, 2021.

[27] C. Zhang, D. Zhou, M. Yang, A.H. Gandomi, A.C. Ammari, and B. Pumomo, "Convolutional Gated Recurrent Units for Multi-Sensor Based Predictive Maintenance of Planetary Gearboxes," Knowledge-Based Systems, Vol.220, 2022. doi: 10.1016/j.knosys.2021.107442.

[28] F. Jiang, Y. Pang, Q. Yang, Y. Wang, and Z. Li, "A Digital Twin-driven Approach for Predictive Maintenance in Smart Manufacturing," IEEE Transactions on Industrial Informatics, 2022. doi: 10.1109/TII.2022.3185517.

[29] A.Soualhi, G. Clerc, H. Razik, and A. Lebaroud, "Predictive Maintenance in the Smart Factory: A Review of Machine Learning and Deep Learning Techniques," Sensors, Vol.22, No.6, 2022. doi: 10.3390/s22062096.

[30] S. Wang, F. Zhang, X. Zhang, Y. Liu, and J. Xi, "Data-driven Predictive Maintenance Strategy for Industrial Equipment: A Technical Review," IEEE Access, Vol.10, pp.17801-17820, 2022. doi: 10.1109/ACCESS.2022.3152872.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors contributing to this journal agree to publish their articles under the Creative Commons Attribution 4.0 International License, allowing third parties to share their work (copy, distribute, transmit) and to adapt it, under the condition that the authors are given credit and that in the event of reuse or distribution, the terms of this license are made clear.